Panel Detection and Splicing Workstation

outline:

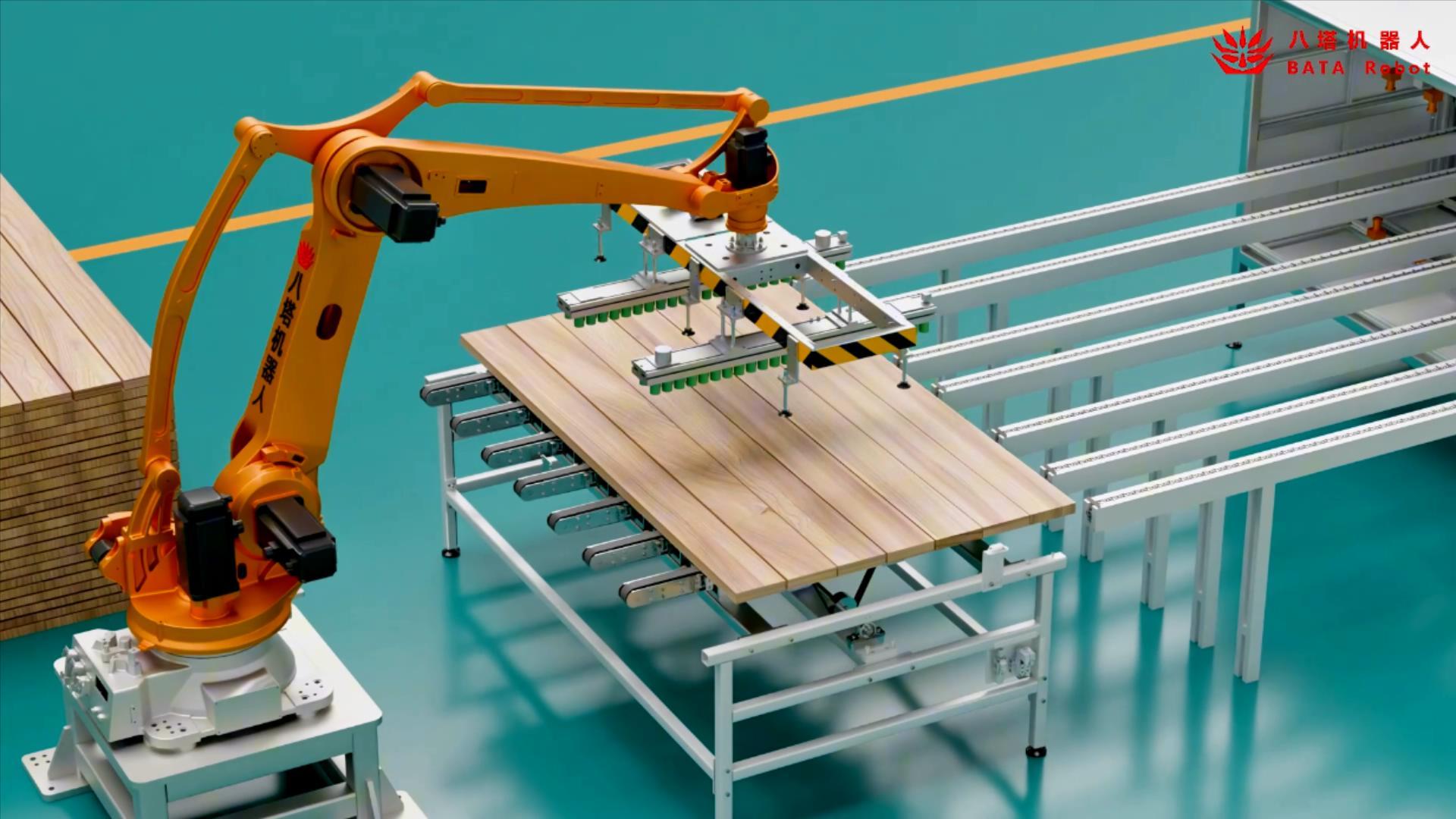

Utilizing AI algorithms, this system performs detailed color difference and texture analysis of wood boards. Combined with proprietary strategic algorithms, it outputs wood board splicing solutions and utilizes a warehousing module for categorized storage, providing a complete board splicing solution for furniture manufacturing. Standard detection speed reaches 2 meters/second and is compatible with multiple sizes.

Category:

Visual inspection production line

key word:

Automatic production line, robot workstation

message

product details

Function introduction: robot destacking, detecting defects such as wormhole, crack, color difference, size and moisture content of wood, and then stacking according to defect classification. It is used for automatic intelligent bonding of multi-layer sponge mattress. Precision composite under visual guidance, suitable for precise bonding of most color, size and thickness sponge mattresses.

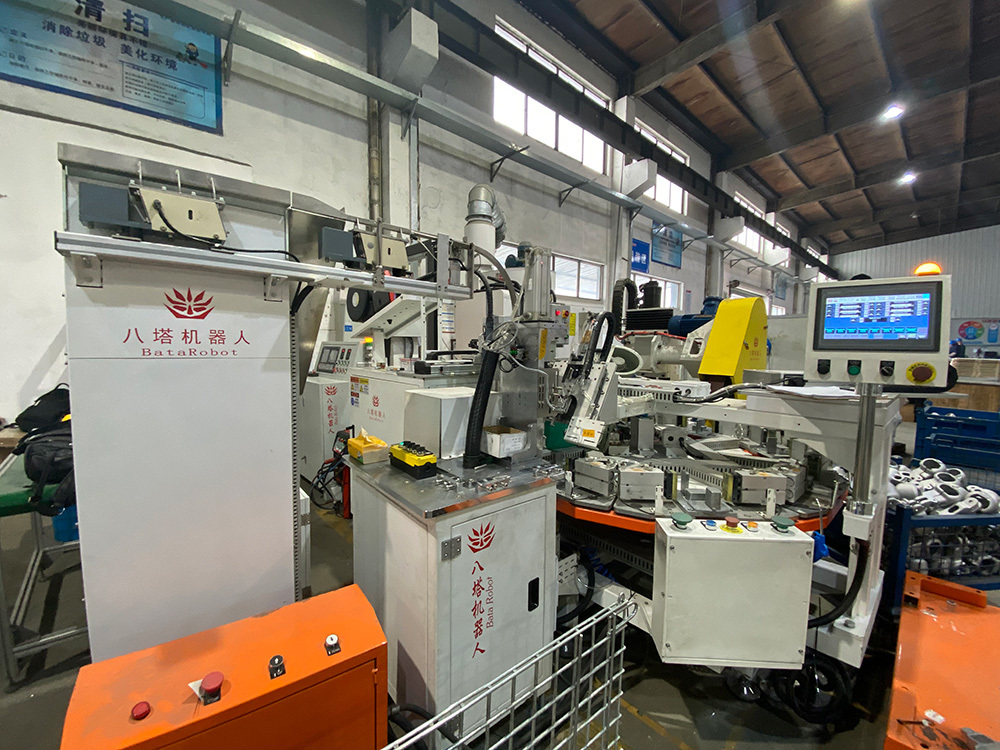

The hardware is mainly composed of stereo vision, robot and claw. The robot with vision can accurately identify the position, model, overall dimension and appearance defects of the workpiece, and then complete the processes of grasping, glue spraying, bonding, stacking, sorting, etc.

At present, the core products are sponge mattress robot production line, spring mattress robot production line, and various robot plus vision "hand eye cooperation" solutions

previous page

next page

Product recommendation

Online Message

Online Message