Plastic net bag visual detection machine

outline:

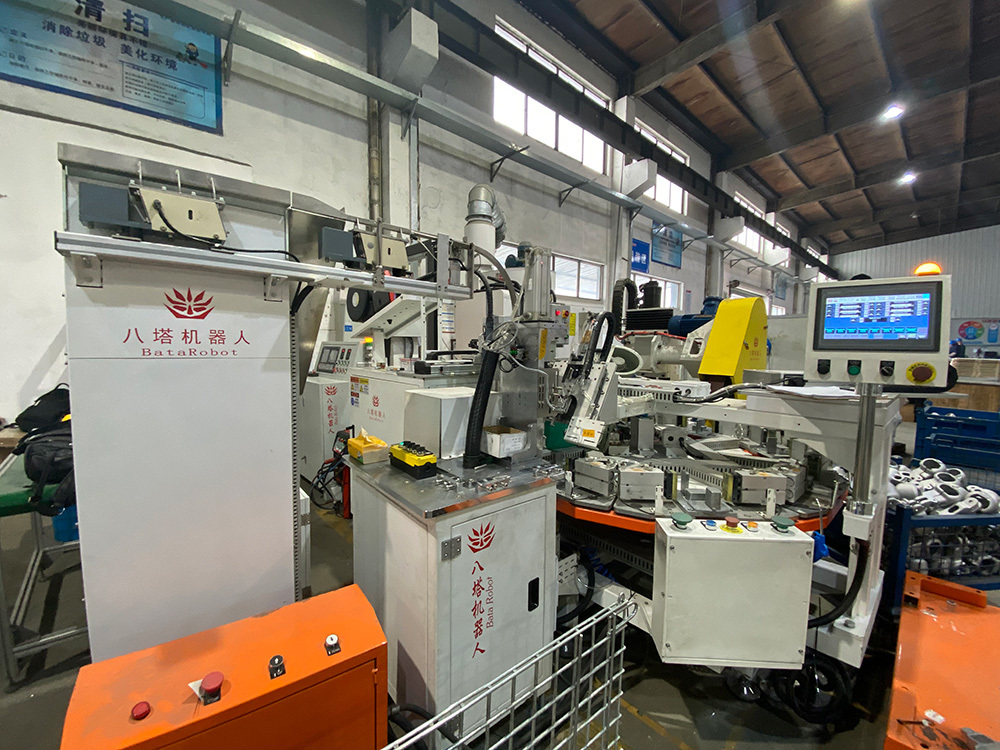

Six sets of vision detection devices work together online to detect flaws of various diameters, colors and meshes of plastic net bags, such as black spots, broken wire, uneven mesh, etc. Characteristics: the robust self-deep learning algorithm is applicable to different specifications of products, customized waterproof special light source can be provided, it can adapt to the working environment where there is splash of water drops, and the specially-designed distinctive suspension mechanism can enhance the image and enjoy the invention patent protection.

Category:

Visual inspection production line

key word:

Automatic production line, robot workstation

message

product details

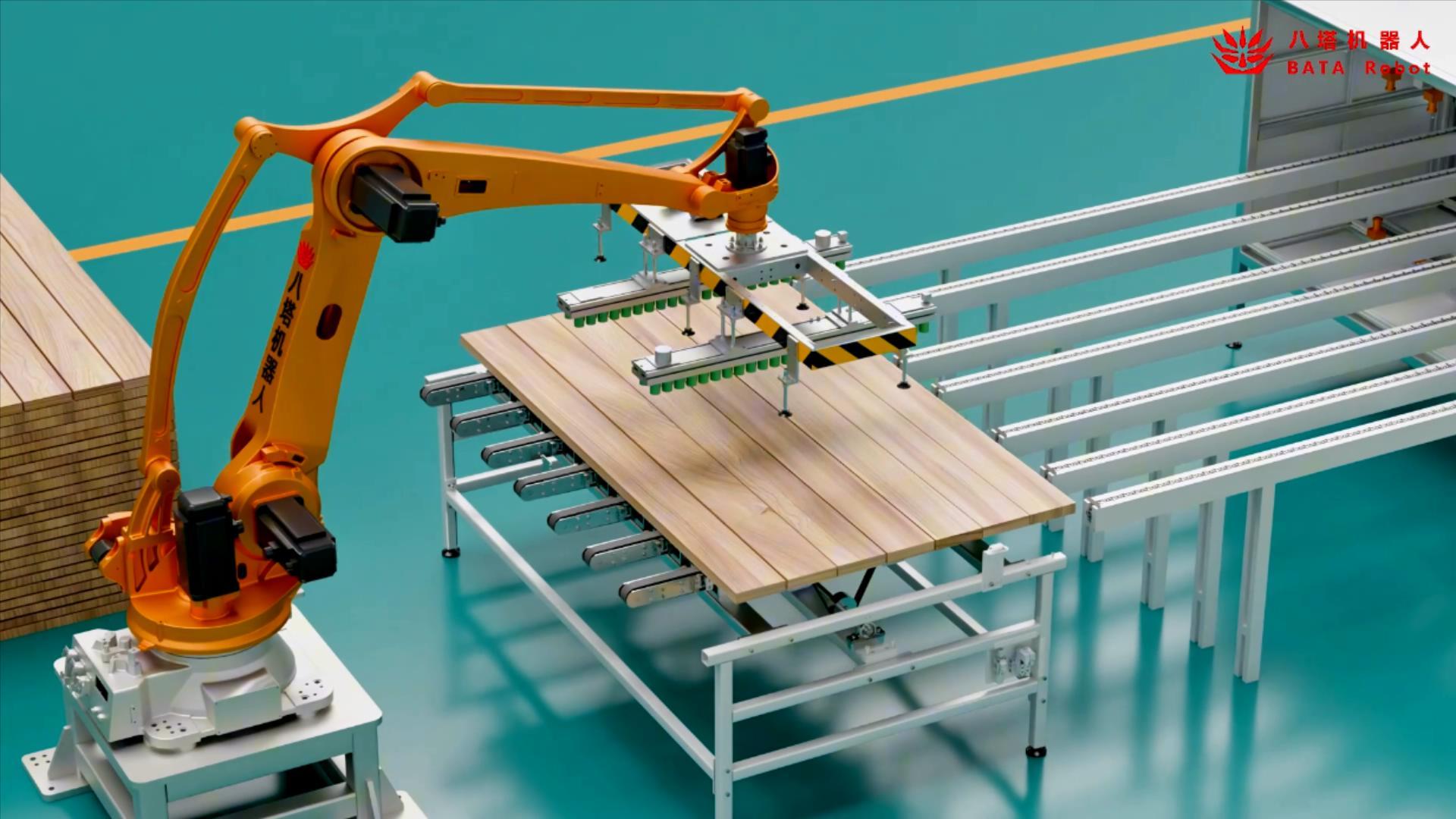

Function introduction: robot destacking, detecting defects such as wormhole, crack, color difference, size and moisture content of wood, and then stacking according to defect classification. It is used for automatic intelligent bonding of multi-layer sponge mattress. Precision composite under visual guidance, suitable for precise bonding of most color, size and thickness sponge mattresses.

The hardware is mainly composed of stereo vision, robot and claw. The robot with vision can accurately identify the position, model, overall dimension and appearance defects of the workpiece, and then complete the processes of grasping, glue spraying, bonding, stacking, sorting, etc.

At present, the core products are sponge mattress robot production line, spring mattress robot production line, and various robot plus vision "hand eye cooperation" solutions

previous page

next page

Product recommendation

Online Message

Online Message