Spring mattress production line

outline:

Functions: multiple robots with visual guidance cooperate with each other to complete multi-layer composite and assembly of the mattress's textile fabric layer, sponge latex layer, spring bag, four sponge stripes, sponge, latex cotton, memory cotton and other multi-layer mattresses. Features: the world's first such application in the production line of spring mattress. Automatically accurately identify the errors of memory sponge, spring bag and other natural materials that are easily deformed and inaccurate, and correct them to the correct position and shape. It can automatically adapt to the textile layer on the mattress surface of various patterns, thicknesses and materials. The whole line has a beat of 50 seconds. Composite precision 3mm. International patent protection for invention.

Category:

Smart mattress production line

key word:

Automatic production line, robot workstation

message

product details

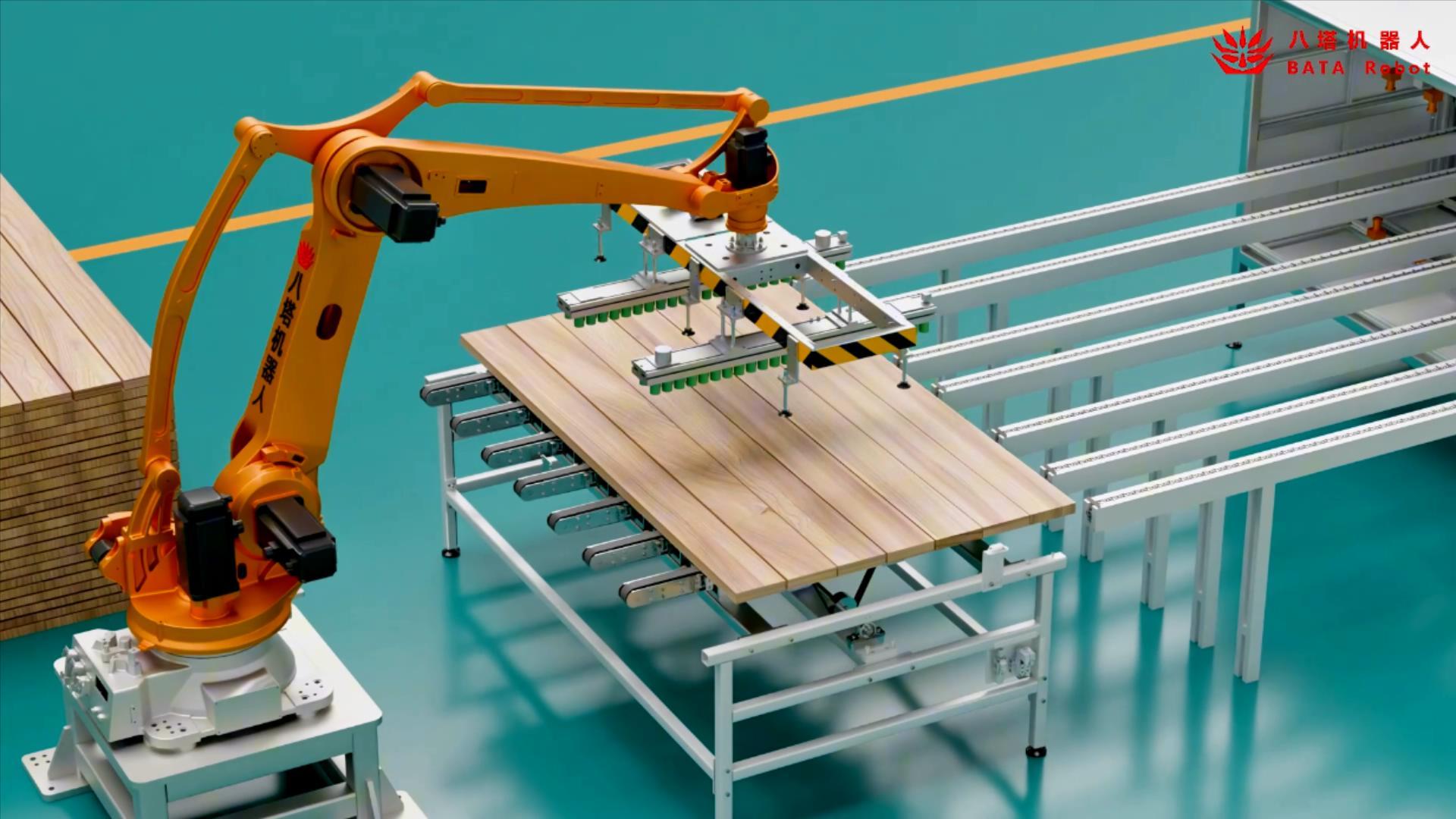

Function introduction: robot destacking, detecting defects such as wormhole, crack, color difference, size and moisture content of wood, and then stacking according to defect classification. It is used for automatic intelligent bonding of multi-layer sponge mattress. Precision composite under visual guidance, suitable for precise bonding of most color, size and thickness sponge mattresses.

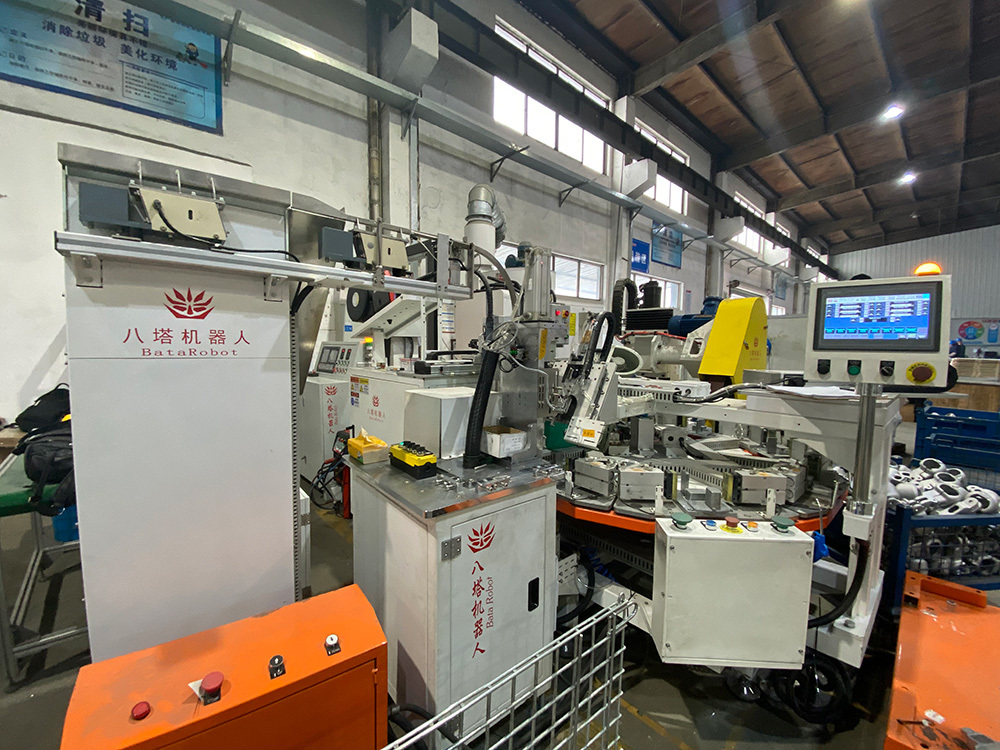

The hardware is mainly composed of stereo vision, robot and claw. The robot with vision can accurately identify the position, model, overall dimension and appearance defects of the workpiece, and then complete the processes of grasping, glue spraying, bonding, stacking, sorting, etc.

At present, the core products are sponge mattress robot production line, spring mattress robot production line, and various robot plus vision "hand eye cooperation" solutions

previous page

next page

Product recommendation

Online Message

Online Message