AGV handling and robot stacking

outline:

Function: AGV autonomous navigation, transport goods to the stacking place. The vision system recognizes the tag and position of the goods, guides the robot to grasp and stack according to the classification of the goods. Features: A variety of AGV navigation uses different application scenarios. AGV and visual robot are combined to achieve a higher degree of automation. The whole process is unmanned and linked with the customer's MES system.

Category:

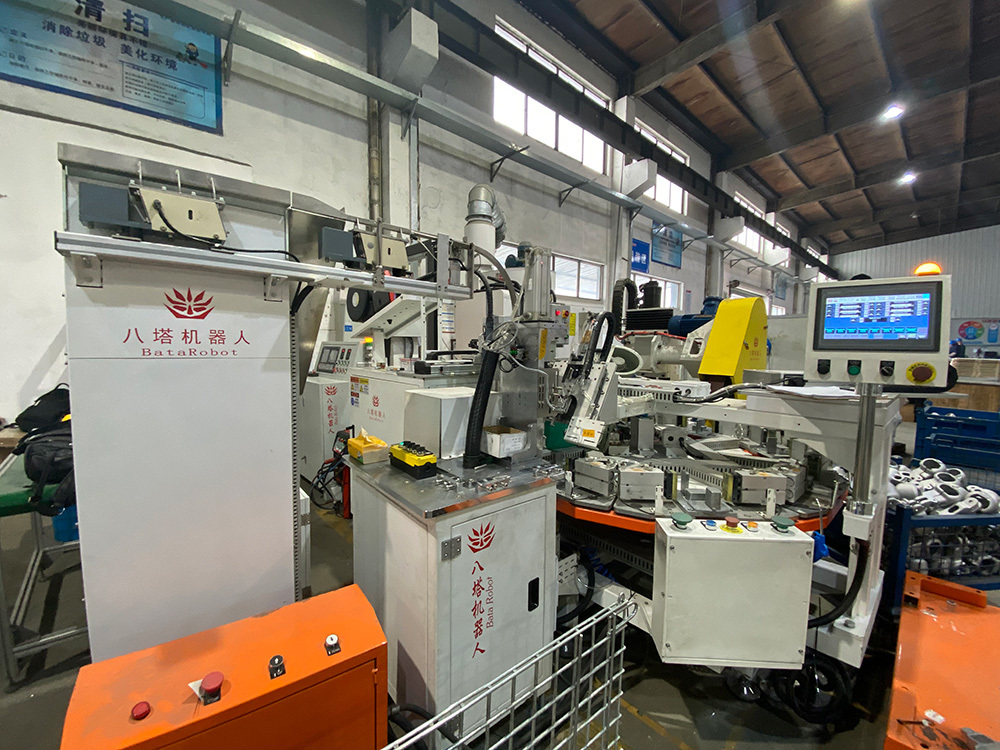

Customized flexible production line

key word:

Automatic production line, robot workstation

message

product details

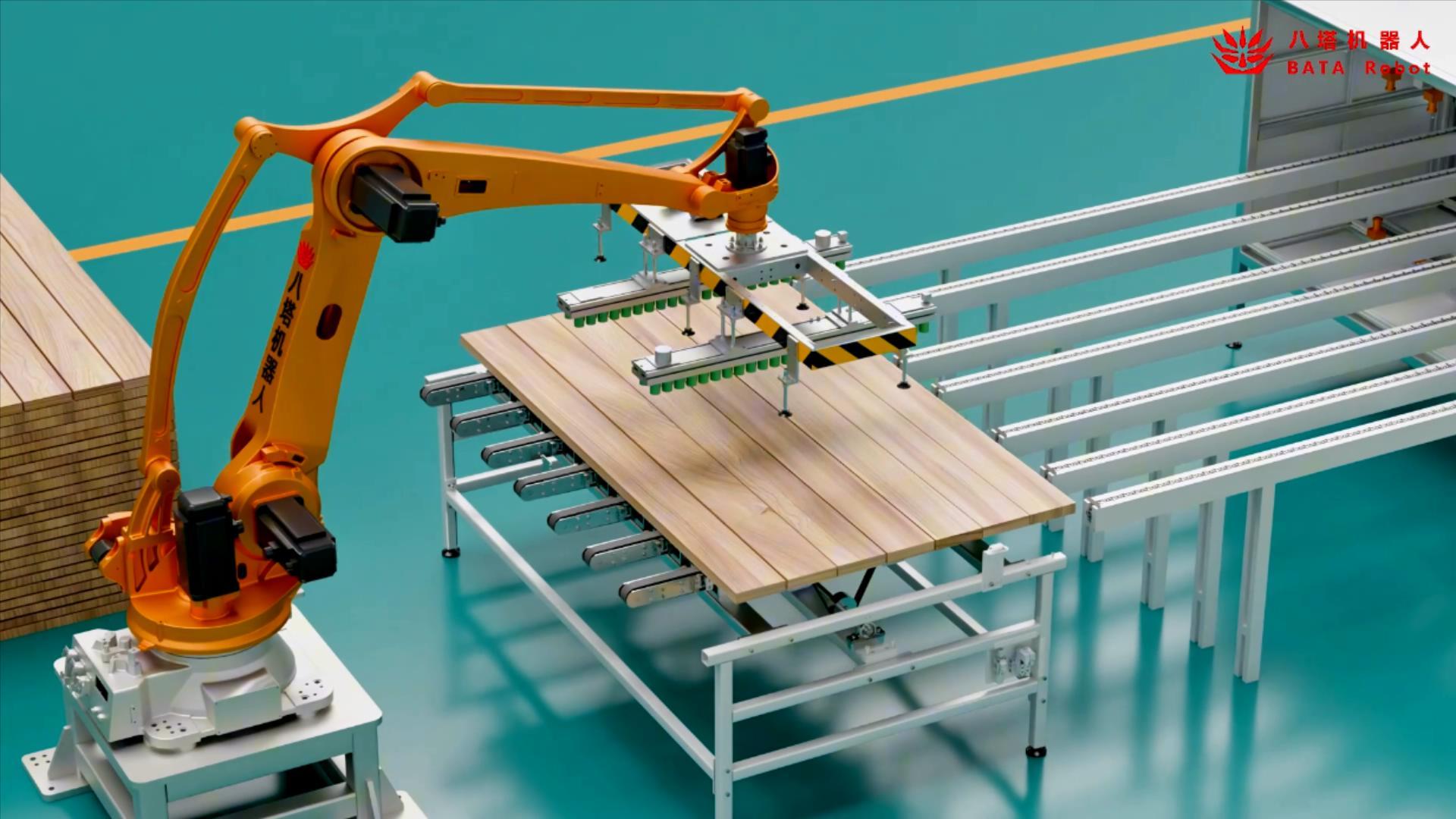

Function introduction: robot destacking, detecting defects such as wormhole, crack, color difference, size and moisture content of wood, and then stacking according to defect classification. It is used for automatic intelligent bonding of multi-layer sponge mattress. Precision composite under visual guidance, suitable for precise bonding of most color, size and thickness sponge mattresses.

The hardware is mainly composed of stereo vision, robot and claw. The robot with vision can accurately identify the position, model, overall dimension and appearance defects of the workpiece, and then complete the processes of grasping, glue spraying, bonding, stacking, sorting, etc.

At present, the core products are sponge mattress robot production line, spring mattress robot production line, and various robot plus vision "hand eye cooperation" solutions

previous page

next page

Product recommendation

Online Message

Online Message